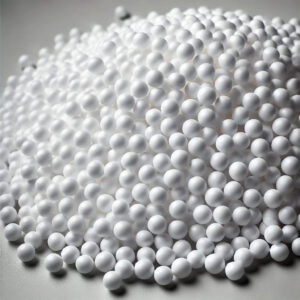

Polypropylene (PP)

Description

Polypropylene (PP) is a thermoplastic polymer widely used in various applications due to its versatility, lightweight nature, and resistance to chemical and environmental stress. It is produced through the polymerization of propylene monomers and is known for several key properties that make it a preferred choice across industries.

Properties:

- Chemical Resistance – Resistant to many chemical solvents, acids, and bases, making it ideal for packaging and chemical containers.

- Lightweight – Lighter than many other plastics, making it suitable for applications where weight is a concern.

- Durability – Exhibits good impact resistance and toughness, making it reliable for structural applications.

- Thermal Resistance – Can withstand higher temperatures (up to 100°C) compared to commonly used plastics like polyethylene.

- Flexibility –

- In homopolymer form, it is stiff.

- In copolymer form (with ethylene), it becomes more flexible with better impact resistance.

Applications:

- Packaging – Used for plastic containers, bottles, and films.

- Automotive Parts – Utilized in dashboard components, bumpers, and interior trims.

- Textiles – Used in polypropylene fibers for rugs, carpets, and non-woven fabrics.

- Consumer Products – Commonly found in storage bins, toys, and kitchen utensils.

- Medical Applications – Due to its chemical resistance and sterilizability, it is widely used for medical devices and equipment.

Reviews

There are no reviews yet.